Concrete Saver

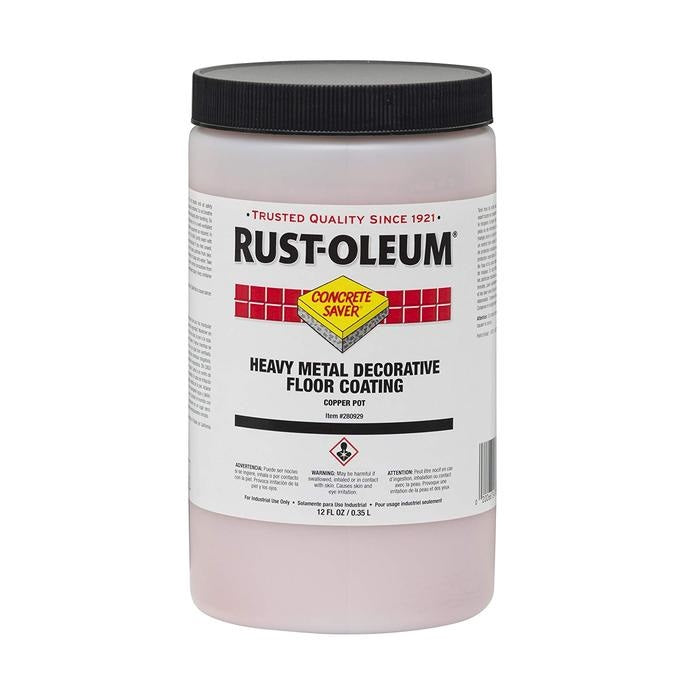

Rust-Oleum Heavy Metal Decorative Floor Coating

Rust-Oleum Heavy Metal Decorative Floor Coating

Couldn't load pickup availability

Heavy Metal is a two component, metallic pigmented floor coating using Polycuramine resin technology. This coating produces a durable high gloss finish with a metalized appearance. The coating is suitable for both interior and exterior applications. For best finish appearance, Heavy Metal should be applied over a black base coat. FastKote Black is commonly used, but it is not the required black finish. It is not allowed to send this item through air mode. Surface mode is enabled for the same. Thus, shipping will be done through surface.

Note : This coating may also be applied as an opaque coating, rather than a metallic finish, by using the Polyurea Universal Tints. In place of the metallic Color Additive, tint the activated material 12% by volume with the selected tint color to achieve proper hiding.

Features of Heavy Metal Decorative Floor Coating

- Easy to apply with long working time - 45 minute pot life

- Fast dry coating accepts traffic in less than 24 hours

- Durable formula protects against chemicals and abrasion

- Use FastKote Polurea Black as a base coat for a more dramatic effect

How to Apply Heavy Metal Decorative Floor Coating

Surface Preparation

The concrete surface must be free of all dirt, grease, oil, fats, and other contamination. Remove surface contamination by cleaning with Pure Strength 3599 Industrial Cleaner/Degreaser, detergent, or other suitable cleaner. Rinse thoroughly with clean, fresh water and allowed to dry.

New Uncoated Concrete : New concrete must be allowed to cure for a minimum of 30 days before application. In addition to the aforementioned cleaning, the concrete must be further prepared by mechanical grinding or acid etch to remove all laitance and produce a suitable surface profile.

Previously Coated Concrete : Previously coated concrete must be in good sound condition with the existing coating tightly adhering to the concrete. In addition to the aforementioned cleaning the existing coating must be sanded to dull the finish and produce a slight surface profile. Remove all sanding dust by vacuum.

Application

Apply only when air, material and floor temperatures are between 40 - 90°F (4.5 - 32°C). Do not apply in direct sunlight or when temperature is rising. Immediately after mixing, pour the material onto the floor in a long, 8 to 12 inch wide stripe. Avoid pouring material over control joints or expansion joints.

Properties of Heavy Metal Decorative Floor Coating

| Manufacturer | Rust-Oleum |

|---|---|

| Resin Type | Cycloaliphatic Hybrid |

| Weight | 11.34 Ltr. |

| Solids by Volume | 96% |

| Volatile Organic Compounds | <10 g="" l="" td=""> |

| Mixing Ratio | 2:1 (Part A:Part B) |

| Induction Time | None required |

| Pot Life | 45 minutes |

| Practical Coverage Rate | 90-100 sq. ft./gal. Coverage rate can vary depending on the texture and porosity of the concrete |

| Dry Times at 70-80° (21-27°C) and 50% RH |

12 hours to 7 days to Re-Coat 12-16 hours Light Traffic 24 hours to Full Traffic |

| Shelf Life | 24 months |

| Safety Information | For additional information, see MSDS |

| Technical Data Sheet | Click here |