Epoxy Shield

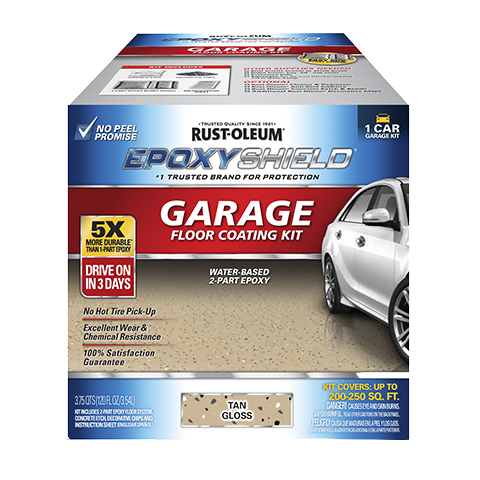

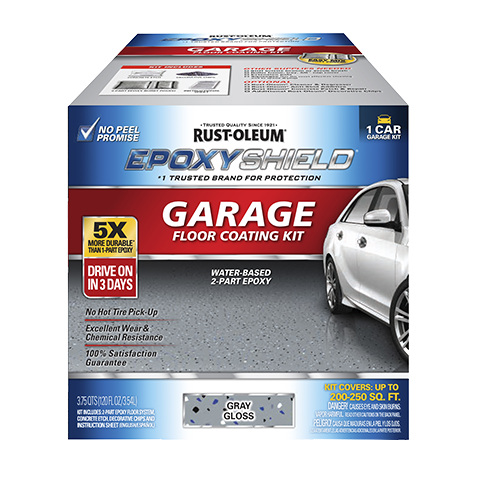

Rust-Oleum Epoxy Shield Garage Floor Coating Kit

Rust-Oleum Epoxy Shield Garage Floor Coating Kit

Couldn't load pickup availability

Rust-Oleum Epoxy Shield Garage Floor Coating is made for the protection and beautification for garage floors. It protect them from motor oil, gasoline, hot tire pick-up, antifreeze, and cracking for many years. The kit of this durable coating contains 2-part epoxy floor system (Part A, Part B), concrete etch, decorative color chips, stir stick, instruction sheet, & DVD. This product is manufactured to use for garage floors that are in good sound conditions, free of curing, agents and sealers.

NOTE: It is not allowed to send this item through air mode. Surface mode is enabled for the same. Thus, shipping will be done through surface.

Features of Garage Floor Coatings

- 2-Part water-based epoxy.

- Long-lasting protection.

- No hot tire pick-up.

- Easy to use and apply.

- Glossy finish.

- Excellent coverage as a kit covers 250 square feet of area.

NOTE: Dont use for unsound previous coatings or for the floors that have moisture issue.

How to Apply Rust-Oleum Epoxy Shield Garage Floor Coating?

Surface Preparation

Allow new concrete to cure for a minimum of 28 days. Sweep away all loose dirt and debris. Remove any oil spots, grease or spills and wash the floor with a suitable detergent or degreasing solution and rinse. Then etch the floor using the Concrete Etch.

Previously Coated Floors : Make sure the floor is clean and dry. Use a wire brush to remove any loose or peeling paint or stain. If floor is sealed, the sealer will have to be removed by grinding or shot blasting. To ensure proper adhesion, scuff sand the entire surface.

Application

Apply only when air, material, and surface temperatures are between 60-85°F (15-29°C) and the surface temperature is at least 5°F (3°C) above the dew point. The relative humidity should not be greater than 85%. After allowing for the induction period, cut in the perimeter of the floor along the wall, or other areas where a roller cannot reach, using a brush or edger before beginning roller application. Use a synthetic ½” nap roller cover on a 9” roller frame to apply an even coat of EpoxyShield onto the surface. Limit the application to 4x4 foot (1.2x1.2m) sections at a time to make it easier to distribute the colored chips onto the freshly coated surface. Scatter the decorative chips up and away from you so they land flat on the wet paint, then continue on to the next section. Note: Fresh paint can be applied over the loose chips lying outside the previously painted area. Maintain a wet edge to prevent lap marks and gloss differences. Only one coat is necessary under most circumstances. EpoxyShield must be used within 1 to 2 hours of initial mixing.

Properties of EpoxyShield Garage Floor Coating

| Brand | Rust-Oleum Epoxyshield |

|---|---|

| Manufacturer | Rust-Oleum |

| Resin Type | Amine cured Epoxy |

| Pigment Type | Varies with color |

| Solvents | Ethylene Glycol Monopropyl Ether, Water G |

| Volatile Organic Compounds | <100 g/l (0.80 lbs./gal.) |

| Mixing Ratio | 3:1 Base to Activator by volume |

| Recommended Dry Film Thickness (DFT) Per Coat |

3.0-3.5 mils (75-87.5µ) |

| Practical Coverage | Approximately 250 sq.ft./kit. (6.2 m2/l) |

| Induction Period | Varies with temperature – See chart in directions |

| Pot Life @ 70-80ºF (21-27ºC) and 50% RH |

Varies with temperature – See chart in directions |

| Dry Times at 70-80° (21-27°C) and 50% RH |

24 hours to Foot Traffic 3 days to vehicle |

| Shelf Life | 5 years |

| Flash Point | >200°F (93°C) Activated material |

| Safety Information | For additional information, see MSDS |

| Technical Data Sheet | Click here |